Having RV slide out issues? Here are the things you should check first when troubleshooting faulty RV slides.

See what to look for when something goes wrong. Plus RV slide out maintenance tips to prevent issues with your slides later on down the road.

Things you can do to prevent costly RV slide out repair issues!

============================

TRANSCRIPT:

Hi I’m Curtis with The Fun Times Guide. And today we’re going to talk a little bit about slide-out mechanisms.

In a perfect world when all is well, a simple push of the button and the slide-out will start moving IN or OUT — depending on which side of the button you push. So what happens when you push the button and nothing happens?

The first thing to do is check the fuses. Slide-out motors are 12 volts — so they have fuses instead of circuit breakers. You go to your fuse panel and identify which fuse pertains to the slide out. And verify that it is good.

If you have run your slide-out up against the stops and held the button for as short a time as an extra second, it is very likely that you blew the fuse — and replacing the fuse is all that is needed.

If indeed your slide-out is not functional and you are camping or at some location where it is not convenient to try and repair it, there is usually a way to manually retract the slide-out. On my trailer, I have a removable hand crank that attaches to a fitting that protrudes out the side of the frame and by turning it left or right it will either retract or extend the slide-out as needed.

The interesting fact is the manuals don’t usually tell you anything about this. And it took me a number of months to discover where this was because it is located directly behind my entry steps. And every time I went to look for it with the steps folded up, I could not see it. So with some searching, you can find where the manual screw attachment is for retracting your slide.

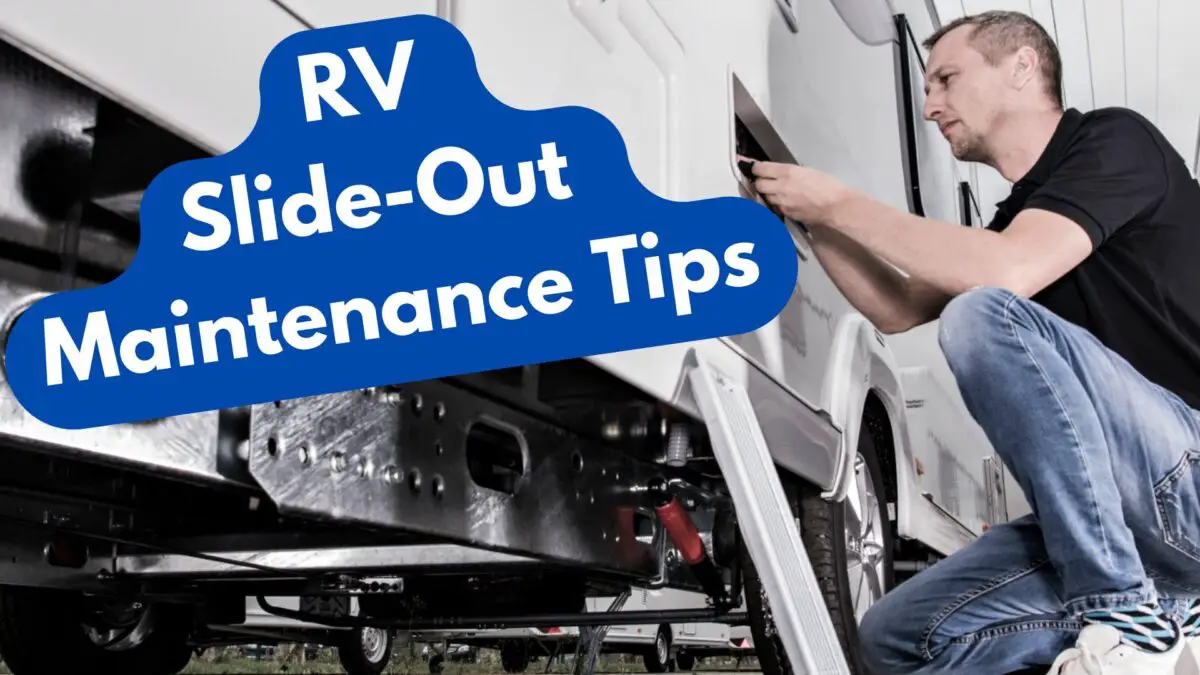

Access to my slide motor is not an easy task. As you can see, the bottom of my trailer is closed in. And the slide motor is located up inside the frame. To remove the underbelly — let’s say the driver’s side of the trailer — the underbelly covering is riveted to the frame and is not removable. But there are screws on the passenger side that you can remove and you can lower that side down to the ground — providing some access to the slide motor area. This is not an easy task and it is one that’ll take a fair amount of time to accomplish.

My slideouts have a gear-driven system where you have a track (a gear track) and the motor runs up and down this track — bringing the slide-out IN and OUT. If the slide-out is not securing properly to the side of the trailer and sealing up good, there are some minor adjustments available to you that will align things so that the slide-out will secure properly.

On this particular type of slide-out it is not recommended to use any lubrication. Because lubrication will attract dirt and grime and will increase the possibility of damage or excessive wear. So I have never lubricated this type of slide-out.

This is just one of probably a half a dozen different types of slide-out mechanisms. Some will allow you to do some maintenance work on your own. While others are complex enough that it is not advised for owners to do much of anything other than confirm that you have electric power to the motor.